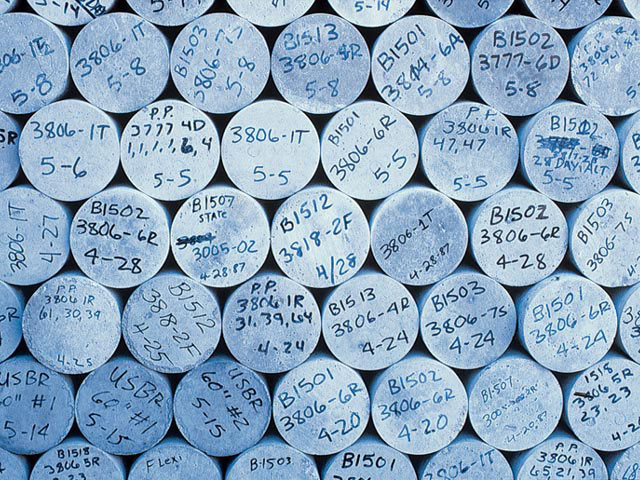

Testing & Quality Control.

Ready Mixed Concrete works closely with General Testing Lab and other testing labs to insure quality control of all our concrete mixes. Inspectors from the lab are actively involved in the design and control of our concrete mixes. By working closely with these testing labs we increase our knowledge and understanding of concrete behavior. This allows us to offer concrete mixes that meet the specifications and required workability needs of our customers. Ready Mixed Concrete also has a full time staff of Quality Control personnel that have extensive concrete training and ACI certifications.

Ready Mixed Concrete believes that quality is achieved by understanding and improving our process. Our inspection team provides our companies with invaluable information that helps us with this never-ending quest.

Associations.

Ready Mix Concrete Company is proud to be affiliated with the following associations. Each, in part, contributes to the preservation of our knowledge, design and production of quality materials for our customers.

Associated Builders & Contractors, Inc. is a national association representing 23,000 construction and construction-related firms in 80 chapters across the United States.

(Learn More)

(Learn More)

The American Concrete Institute is a leading authority and resource worldwide for the development and distribution of consensus-based standards, education, training programs, and much more.

(Learn More)

(Learn More)

The Home Builders Association of Lincoln (HBAL) provides many benefits to its 900+ members and offers numerous ways for members to grow their businesses.

(Learn More)

(Learn More)

The Association of General Contractors is the nation’s largest and oldest construction trade association, established in 1923.

(Learn More)

(Learn More)

The mission of the National Ready Mixed Concrete Association is to provide exceptional value for members by responsibly representing and serving the entire ready mixed concrete community through leadership, promotion, and education.

(Learn More)

(Learn More)

Since 1983, The Nebraska Concrete & Aggregates Association has worked diligently to represent the concrete industry through ongoing training and education, promotion, safety concerns, legislative oversight, and long-range planning efforts.

(Learn More)

(Learn More)

The Lincoln Builders Bureau was founded in 1932 by general contractors, architects and engineers who wanted a local plan room to house blue prints for sub contractors and suppliers.

(Learn More)

(Learn More)